PERI is a global leader in formwork and scaffolding systems for the construction industry. The company places great emphasis on innovation and the highest quality standards. ForkOn is a pioneer in fleet management, offering manufacturer-independent solutions for forklift and AGV fleets. The combination of cloud software and telematics hardware enables optimized fleet management.

PERI and ForkOn have joined forces to optimize the fleet management of the renowned manufacturer of formwork and scaffolding materials and leading 3D concrete printing provider. This innovative partnership aims to increase the efficiency and safety of PERI's forklift fleet.

Reinhold Strobel, Head of the Logistics Competence Center at PERI Germany, is passionate about improving operational processes and increasing safety. Challenges in fleet management led him to ForkOn, a leading provider of manufacturer-independent solutions.

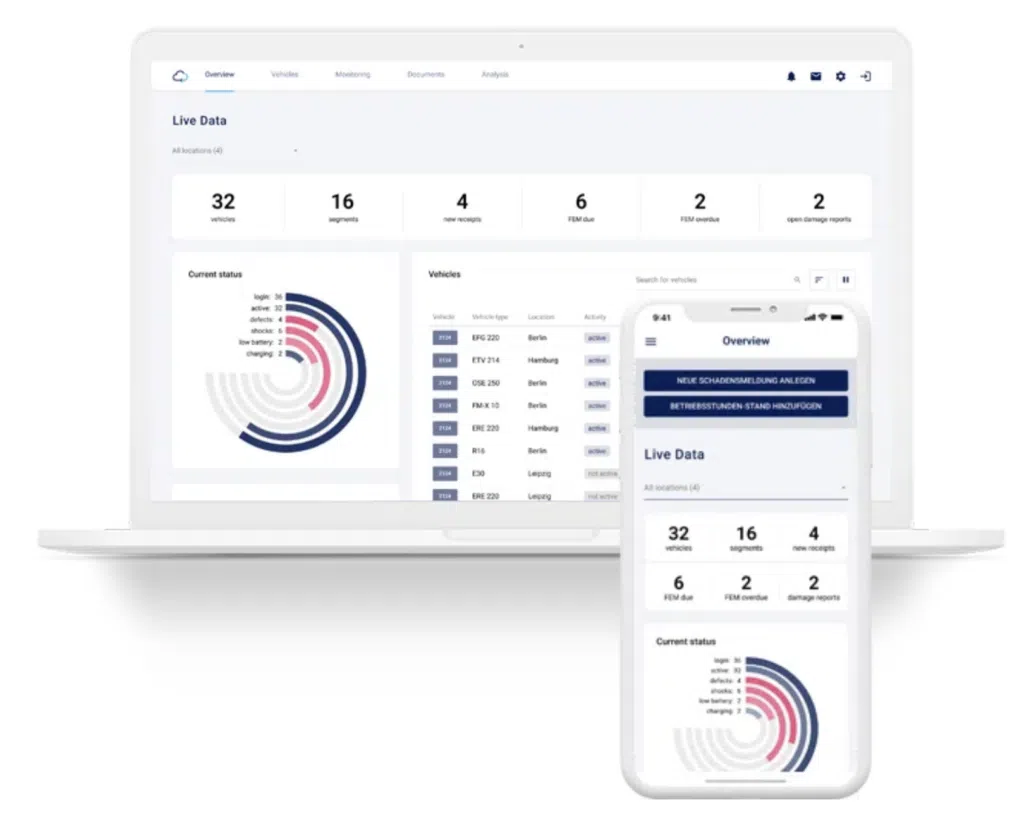

ForkOn offers a comprehensive solution based on state-of-the-art cloud software and advanced telematics hardware. This equipment enables companies to manage their fleets with unmatched visibility, control, and optimization.

Tim Klauke, CEO and founder of ForkOn, explains:

Before this partnership, PERI faced challenges such as a lack of real-time fleet monitoring and inefficient maintenance documentation. Strobel recalls: "Before implementing the system, we struggled to maintain accurate oversight of our forklift fleet. This led to manual processes and limited insight into utilization and costs."

The implementation of ForkOn's solution led to a noticeable improvement.

"Implementing the system brought several benefits. We were able to standardize our processes, digitize damage reports and technician assignments, and centrally store important documents. This has reduced downtime and increased efficiency. Additionally, automatic inspection reminders minimize risks," adds Strobel.

Of particular note is the system’s utilization module.

"The system's software and utilization module proved particularly valuable. These features enable us to optimally manage our fleet and use resources efficiently," emphasizes Strobel.

The successful collaboration led to measurable results.

In conclusion, Strobel emphasizes the positive collaboration with ForkOn: "The collaboration with ForkOn during the implementation process was extremely positive. The support was exemplary, our contacts were always available and often responded the same day. I would rate the likelihood of recommending ForkOn with a 10. ForkOn's solutions have improved our processes and brought positive changes to our fleet management."